Industrial

applications, for example, the production line floor are normally electrically

noisy atmosphere. Electrical noise either conducted or radiated as

electromagnetic interference (EMI), can really disturb the correct operation of

other equipments. Insulation secures a cable mechanically from scraps and

scraped spot and environmentally from dampness and spills. However insulation

is transparent to electromagnetic vitality and offers no security. Shielded cable

is required to battle the impacts of EMI.

Cables can

be a main source of exchange for EMI, both as a source and receiver. As a

receiver, the cable can get EMI radiated from different sources. A shield works

at both. Being a source, the cable can either conduct noise to other hardware

or act as a radio wire radiating noise.

The

essential approach to battle EMI in cables is using shielding. The shield

encompasses the inward signal or power-conveying conductors. The shield can work

on EMI in two ways. To start with, it can reflect the vitality. Second, it can

get the noise and conduct it to ground. In either case, the EMI does not

achieve the conductors. In either case, some vitality still goes through the

shield, yet it is so exceedingly weakened that it doesn't cause interference.

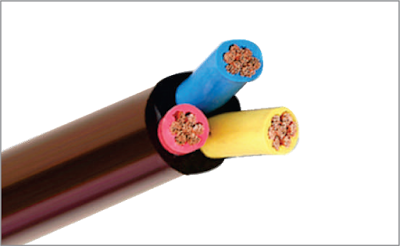

Cables accompany different degrees of

shielding and offer changing degrees of shielding viability. The measure of shielding

required relies on various factors, incorporating the electrical environment in

which the cable is utilized, the expense of the cable—why pay for more shielding

than you need?— and issues like cable weight, diameter and flexibility.

An unshielded cable for industrial applications

normally is utilized in a controlled atmosphere—inside a metal cabinet or a

conduit, where it is shielded from encompassing EMI.

Here are two kinds of shielding which are used for cables:

braid and foil

Foil shielding

utilized a lean layer of aluminum, normally appended to a transporter, for

example, polyester to include quality and toughness. It gives 100% scope of the

conductors it encompasses, which is great. It is lean, which makes it harder to

work with, particularly while applying a connector. Normally, as opposed to

endeavoring to ground the whole shield, the channel wire is utilized to end and

ground the shield.

A braid is a

woven cross section of uncovered or tinned copper wires. The braid gives a

low-resistance way to ground and is easy to termination by crimping or

fastening while appending a connector. But, braided shields don't give 100%

scope. They permit little gaps in coverage. Contingent upon the tightness of

the weave braids ordinarily give between 70% and 95% coverage. At the point

when the cable is stationary, 70% is normally adequate. In fact, you won't see

an expansion in shielding adequacy with higher rates of scope. Since copper has

higher conductivity than aluminum cable

and the braid has more bulk for conducting noise, the braid is more viable as a

shield. However, it adds size and cost to the cable.

For

exceptionally noisy situations, various shielding layers are frequently

utilized. Most regular is utilizing both a foil and a braid. In multi-conductor

cables, singular sets are sometimes shielded with foil to give crosstalk security

between the sets, while the general cable is shielded with foil, braid, or

both. Cables likewise utilize two layers of foil or braid.

Practical Guidelines for

Effective Shielding

- Ensure you have a cable with adequate shielding for the application's needs. In decently noisy situations, a foil alone might give satisfactory security. In noisier situations, consider braids or foil-braid blends.

- Utilize a cable suited to the application. Cables that experience rehashed flexing normally utilize a spirally wrapped shield as opposed to a braid. Avoid foil-only shielding on flex cables subsequent to persistent flexing can tear the foil.

- Ensure the equipment that the cable is associated is legitimately grounded. Utilize an earth ground wherever conceivable and check the connection between the ground point and the equipment. Eliminating noise relies on upon a low resistance way to ground.

- Most connector outlines permit full 360° end of the shield. Ensure the connector offers shielding adequacy equivalent to that of the cable. For instance, numerous normal connectors are offered with metal-covered plastic, cast zinc, or aluminum back shells. Ignore both over specifying and paying for more than you require or under specifying and getting poor shielding execution.

- Ground the cable toward one side. This disposes of the potential for noise prompting ground circles.